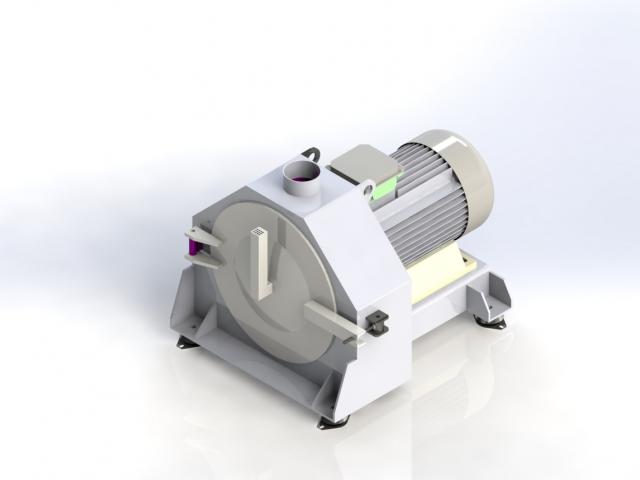

Mill blades and hammers:

Suitable for grinding and bran products with a lot of fiber, difficult to grind with other systems.

Suitable for grinding products with a high content of fat is difficult to mill with other systems.

The entry of the product is positioned on the top, has a grid of perforated sheet of large size which almost completely surrounds the rotor, a particular air intake allows a suction that allows a continuous washing of the grid.

The direction of rotation can be either clockwise or counterclockwise, this allows a more uniform wear of the hammers.

Photogallery

-

Technical Description

Technical data

Rotor with discs mounted directly on the crankshaft with fixed cutting blades made of special steel and oscillating hammers of hardened steel. Special air connecting point on the hatch to substantially raise the yield and the evacuation of the flour. Armor made of steel to slow down the product, allowing the cutters more intense. The grill which surrounds the rotor with large surface area. A special air flow allows constant cleaning of the grid. Large front hatch for easy inspection and change of the grill.

Functioning

The entry of the product is placed at the top and a large output is placed under the mill. From the exit you can connect, via a hopper, a pneumatic transport or an auger or other type of transport. Direction of rotation either clockwise or counterclockwise. We recommend the alternate operation clockwise/ anticlockwise in order to have a uniform wear of the blades and hammers. Silent and vibration-free operation. A very good machine for the grinding of bran, and any type of fibrous product such as straw and sawdust, also used for grinding waste cleanup of cereals.